Rapid technological change, need of rationalization in industries and existence of out of date plant and machines are the necessities of replacement studies.

One of the frequently encountered problems in business enterprises are to decide whether existing equipment is replaced with a new and modern facility. Wear and tear of equipment, coupled with rapid technological growth make the replacement an even present problem. Incorrect thinking about replacement may lead to serious difficulties from both financial viewpoint and a competitive position.

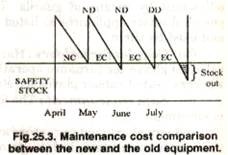

Fig.25.3 shows the maintenance cost per unit time of presently owned equipment (A) and new equipment (B) (under consideration for replacing the present equipment).

ADVERTISEMENTS:

Fig. 25.3 clearly shows that new equipment reduces the maintenance cost but it involves a high average capital cost. It is decided to replace equipment when the maintenance and capital costs of equipment ‘A’ is more than the average capital and operating costs of replacement i.e. the equipment ‘B’.

The new trend is to replace all those equipments which are not operating as productively as possible.

Reasons for Replacement:

Equipments are generally considered for replacement because of the following reasons:

ADVERTISEMENTS:

(a) Obsolescence

(b) Deterioration

(c) Working conditions

(d) Inadequacy

ADVERTISEMENTS:

(e) Rapid technological changes.

(a) Obsolescence:

It may be due to lessening in the demand for the services rendered by the equipment or by the availability of more efficient equipment.

(b) Deterioration:

Deterioration is the decline in performance of equipment due to wear and tear, misalignment etc.

(c) Working conditions:

It may be thought of replacing old equipment’s and machinery which create unpleasant, i.e., smoky, noisy etc. and hazardous working conditions causing worker unsafely and leading to accidents.

(d) Inadequacy:

When the equipment does not have sufficient capacity to meet the present demand and is inadequate to meet the challenges of making new products or existing products in large quantities.

(e) Rapid technological changes:

Technology is progressing rapidly. Newer and better equipment’s are being developed and turned out every year. If the management does not go for a change in the equipment or machinery, the unwarranted manufacturing cost arising from obsolete equipment’s will reduce profits and seriously impair the concern’s competitive position in the market. Rapid technological changes cause loss in the value of machinery.